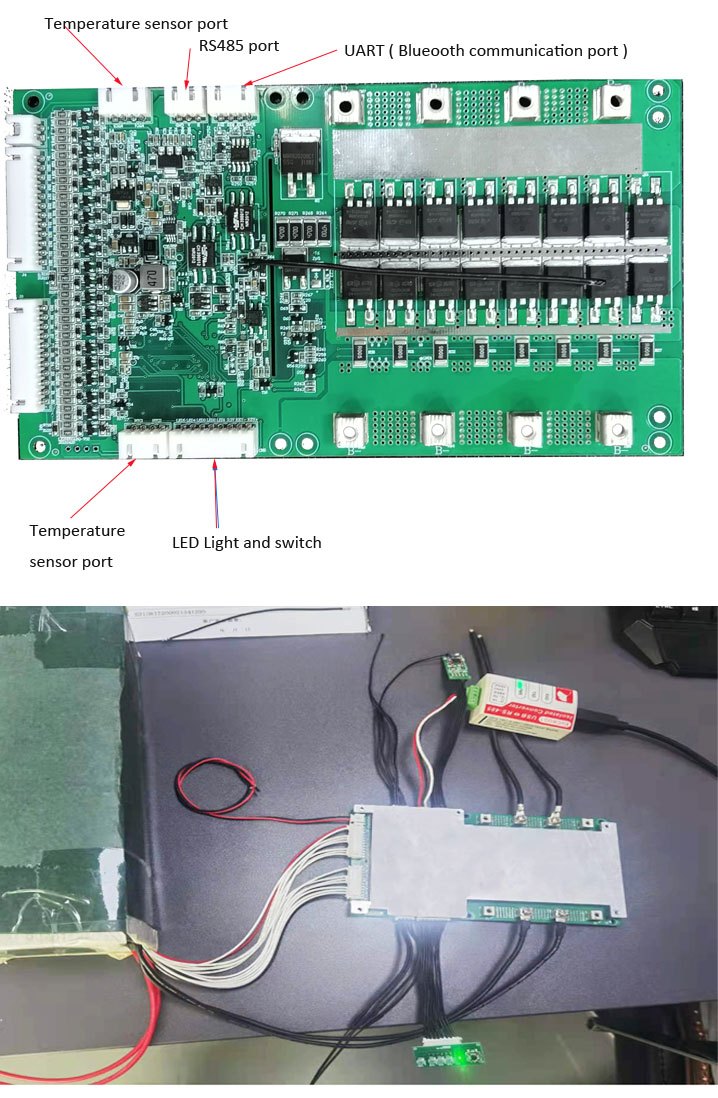

12S~20S Li ion Battery BMS development( With UART ,RS485 , Blueooth APP communication function ) This BMS LLT2050ABQ-V01 designed and produced by Shenzhen LLT Electronic Technology Co., Ltd. which will be suitable for the protection and management of 12-20 strings of lithium-ion power battery systems. it can be widely used in the power supplier filed in according to the different application backgrounds.

The T2050ABQ-V01 battery BMS can monitor the single series cell voltage, charge and discharge current, and detect temperature of sampling place in real time, estimate the remaining power of the battery pack, and perform charge balance. BMS has such display function : Power amount ,working status ,abnormal working etc . BMS can communicate with external devices such as host computers, chargers, mobile phones with the help of external communication module to import parameters setting, receive commands. In the eventof meeting abnormal conditions such as (cell overvoltage, cell undervoltage, overtemperature, overcurrent), the BMS can send out an alarm message, and turn off the charging or discharging MOSFET to protect the battery pack from any possible damage. This BMS has switch and charging activation function. It is equipped with a serial communication host computer,which has the functions of monitoring real-time battery pack data and status, protection board controlling status, reading and writing, import and export of fault parameters, calibration, voltage and temperature comparison with basement criterions , and program upgrade. Supporting RS485 communication to realize RS485 communication between BMS and externaldevices .

Features and characteristics of this BMS :

Dimension :180*100*10mm

Power supply to the BMS : this BMS was powered directly from the battery pack , and power supply voltage range is 16V-72V

Detection precision:

(1) Single voltage detection precision: ±10mV.

(2) Battery pack voltage detection: ±200mV.

(3) Temperature detection accuracy: ±2°C.

(4) Accuracy of charge and discharge current detection: ±1% (0A~50A).

(5) SOC estimation accuracy: ≤±5%.

(6) Number of fault storage: ≥10.

Working environment

a. Working temperature: -40~+60℃; b. Storage temperature: -40~+80℃;

c. Working humidity: ≦98% (25℃).

Features:

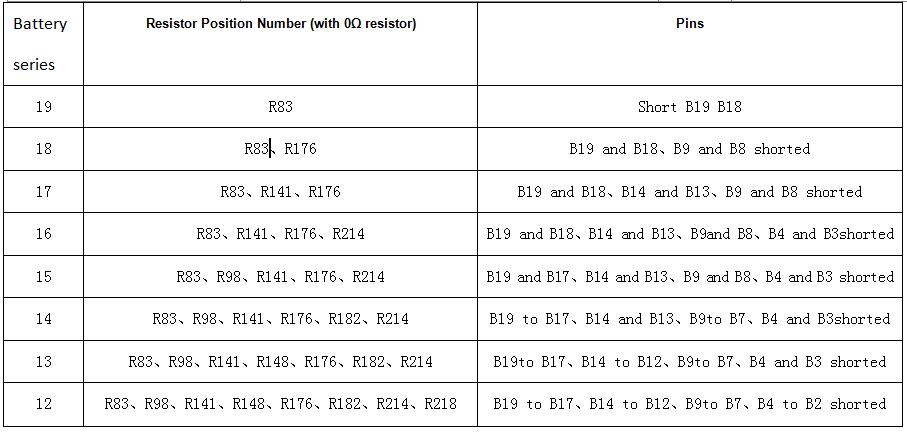

1) Suitable cell series range: 12 to 20 sereis cell will be suitable

2) Number of temperature sensors that can be connected: 4 road NTC, 10kΩ@25℃

3) Rated discharge current: Max continuous current 60A.

4) Rated charging current: Maximum continuous current 60A

Hardware protection functions which has overcharge, overdischarge, overcurrent, short circuit, and temperature protection functions

5) Power supply: battery pack (no auxiliary power supplier)

6) Work control: external power supply switch

7) Communication interface: UART (with isolation)

8) RS485 communication module: powered by BMS (with isolation)

9) RS232 communication module: powered by BMS (with isolation)

10) Temperature rise during maximum discharge: less than 40℃

11) Charging balance current: not less than 50mA.

12) Power consumption: in normal working status: the current is less than 30mA.

During work off status : The current is less than 300uA.

13) The weak current switch supports start with load, wake up from sleep, and switch on and off.

14) 4 LED lights power display, 1 pcs of alarm light

15) With precharge and pre-discharge circuit to provide safer and reliable working performance for the BMS when it needs large current discharge and large current charge , the BMS will make sure the stable current supply

with external LED switch to turn off or turn on the BMS with more reliable wand conveniently way